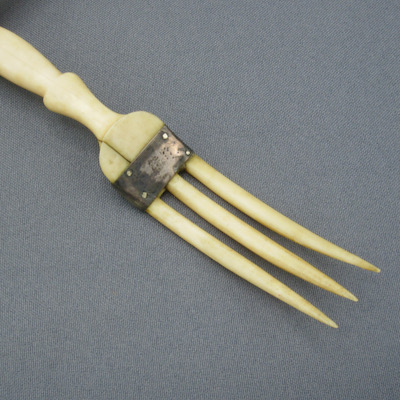

This bone salad serving set, which measures 10.5 inches long, appears to have been made in France, c.1880. Long ago, one of the fork prongs broke off and was repaired by a silversmith, who added a wide band to help secure the break. As many antique bone salad servers were made with silver handles or embellishments, this silver repair seems appropriate.

Here’s a more upscale set of French salad servers with original ornate silver handles.

Photo courtesy of Catawiki